Pixel Control System

The Pixel Control System comes with the Pixel Car Controller, Top-of-Car Controller, Car Operating Panel Controller, Landa™ positioning system and any hall nodes – all depending on the job requirements.

Powerful yet simple-to-use diagnostic stations are built into each access point, which include capabilities for complete on-site reprogramming of the elevator “Personality” parameters, motor control drive unit parameters, fault diagnostics and event diagnostics play back.

The Pixel Control System utilizes a CAN driven system, a more efficient form of serial communication that allows for future upgrades. This eliminates the extra wire count, decreases cost and saves field labor time.

PM synchronous motor controls is available for gearless and MRL applications, with a variety of encoder interface options, including EnDat and Hyperface.

Touch & Go™ Interface

The LCD graphical user interface allows for easier adjustment and maintenance. The Touch & Go™ interface is the same on all three access points, allowing you to adjust and troubleshoot from various locations.

Three Points of Access

Gain access to the user interface at three locations (controller, top of car, car operating panel) throughout the elevator system for quick and easy installation, adjustment and maintenance.

Landa™ Positioning System

An absolute reading system, the Landa™ positioning system is made up of two complete sensor head units and gives a position accuracy of 32 positions per inch (0.8 mm) throughout the entire hoistway. This positioning system creates a faster installation and less maintenance by eliminating all hoistway vanes and switches. With Landa™, the system always knows where the car is located.

Pixel Traveling Cable

Elevator Controls’ Traveling Cable for Pixel simplifies installation, and saves you time & maintenance costs by preventing installation errors. All of our traveling cable is custom labeled to quickly and easily match Pixel terminal strip labeling. Call us today to order traveling cable with your Pixel controller.

Applications

- Modernization or New Construction

- Elevator Controls Pixel Controller

Benefits of Pixel Traveling Cable

- Reduces installation errors and saves time

- Special cable printing to match Pixel terminal strip labeling

- Easy installation

- Save time during installation and maintenance

- Can be used for front and rear openings

- Custom labeled Pixel traveler cable for all jobs with standard solid state door operators

- Single Coaxial Conductor

Features

- Steel Core Size: 5/32″

- Breaking Strength: 2800 lbs – Diameter: 1.31″

- Five 20 AWG Shielded Pairs – Eighteen 18 AWG Wires

- Six 14 AWG Wires

- Kellem Grips Available

Interact™ Monitoring System

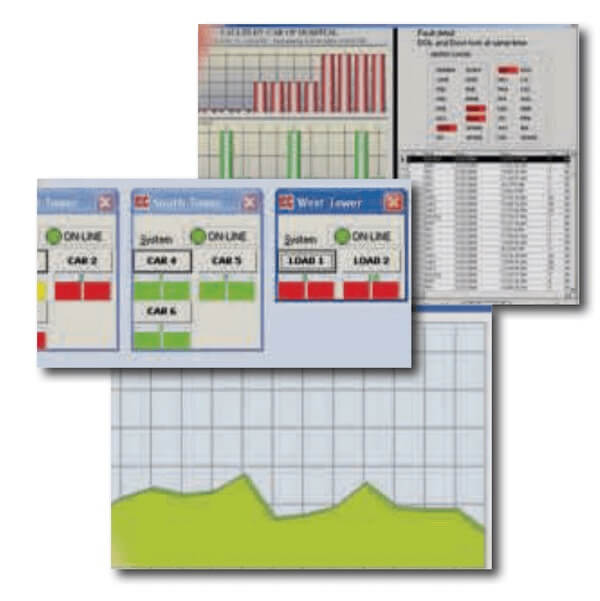

Interactᵀᴹ provides simultaneous display of multiple elevator systems on a single screen.

Intuitive point-and-click interaction and menu-driven navigation make Interactᵀᴹ powerful, yet easy to use. All reports can be graphically represented, and user preferences are easily set to format graph types, styles, display colors and even 3-D format representation.

A single multi-port PC running Interactᵀᴹ for Windows® provides transparent connections that are automatically created in the background – no more dialing and disconnecting one system at a time to get data or fumbling with cumbersome switch boxes to access multiple elevator banks.

Double-click on an elevator or system icon for real-time “drill down” access to interactive viewing and reporting options, including:

- Traffic data and analysis

- Operating sequence playback for troubleshooting

- Fault logs

- Elevator performance monitoring

- Elevator system management

An online support manual with help screens resides within the program itself for instant context sensitive access to help. Interactᵀᴹ is interactive Command and Control for Elevators.

Traffic Analysis

Interactᵀᴹ provides the ability to access extensive menus containing numerous traffic reports, call management reports, and charts. Reports include calls per hour, per opening, per type (up or down) and per day; including wait times with minimum, maximum, average and standard deviation; and call distribution per wait time, per date, per hour, per floor, and per call type. Reports are easily exported in multiple popular formats.

Elevator Management

Interactᵀᴹ elevator management and monitoring software enables comprehensive interaction with the elevator system and management capabilities including: event scheduling with start/stop intervals, floor service car mapping and call lock-outs, security control parameters, extensive monitoring and flexible management functions, charts, reports and export capabilities.

Troubleshooting Tools and Fault Log

Interactᵀᴹ elevator troubleshooting features provide a wealth of information easily accessed via multiple menus, including graphs that detail fault types and status of critical elevator signals over time listed by type, by car, by date, by time, by floor and more. Fault details are listed with number of occurrences and associated relevant information including car position, car status, date/time of occurrence and more.

Vertical Integration

At Elevator Controls, our Vertically Integrated Pixel control system includes software, hardware, mounting kits, peripheral connectivity and user interfaces. The Pixel Control System has been engineered to optimize all facets of elevator operation and installation, including the labor hours needed to install the complete control system. The Pixel Vertically Integrated system reduces cost and improves efficiency on every project.

3 Points of Access

Built-in On-Board Diagnostic stations are provided inside the Controller, in the Top-of-Car (TOC) Box, and in the Car Operating Stations. A full-color LCD screen and swift navigation knob keep everything you need right at your fingertips.

Car Positioning

The Landa Absolute Encoded Positioning System’s stainless steel tape and dual non-contact sensor heads provide redundancy for safe, smooth and accurate operation. No hoistway door zone magnets, no slow down or hoistway access limit switches are needed. Setup and adjustments are performed at the On-board Diagnostic Stations, not in the hoistway.

Mounting Brackets, Hardware and More

We provide you with mounting brackets, wire harness, and hardware for the TOC Box and the Landa Positioning System, reducing the need to source parts elsewhere.

Motor & Drive Control

Pixel’s powerful microprocessor calculates and generates an optimum speed curve for every run, based upon user-programmable parameters. Pixel allows you to customize the ride for your desired level of comfort and performance.

Pixel Traveling Cable

Our Pixel Traveling Cable is custom-labeled to match the terminal labeling inside the controller and in the TOC Box, increasing installation efficiency and helping to eliminate installation errors.

Top-of-Car Box

Pixel’s TOC Box includes a Cartop Inspection Station, work light and service outlet, all pre-wired, tested and ready to use. A 6VDC alarm bell is also available. The Pixel TOC Box also serves as the junction box for traveling cable connections.

CANbus Serial Communication

Pixel utilizes CANbus technology for reliable communication, reducing conductor counts and cost in both the traveling cable and hoistway cabling. Pixel provides a plug-and-play Cat5e hall fixture wiring package which connects quickly and minimizes the chance of wiring mistakes.

Operational Platform

The Pixel Control System is a complete solution for your entire portfolio of elevators, available for Traction AC, DC (geared, gearless, MRL) and Hydraulic elevators.

Resources

| Title | Link |

|---|---|

| EC MRL Product Brochure | |

| EC_Data_Form_DC_Controller | |

| EC_Data_Form_Hydro_Controller | |

| EC_Data-Form_AC_Controller | |

| Pixel Electric Elevators TSSA Compliance Test Procedures | |

| Pixel Hydraulic Elevators TSSA Compliance Test Procedures | |

| Pixel Hydraulic Instalation and adjustment | |

| Pixel Traction Installation and Adjustment V02 |

Additional resources are available in the