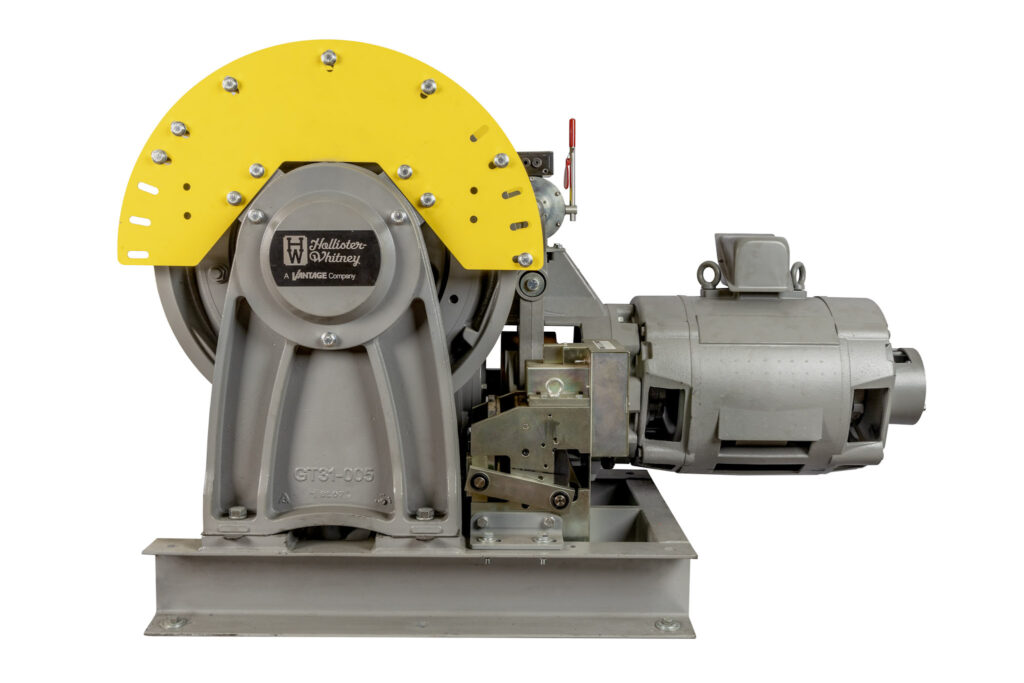

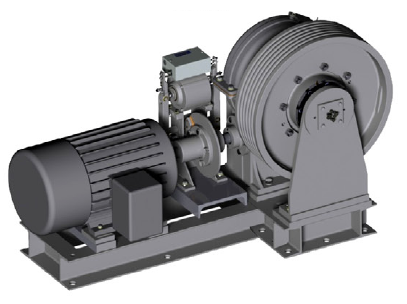

Hollister-Whitney offers a complete line of heavy-duty overhead traction machines, featuring speeds of up to 500 feet per minute. With machines and bearings designed and tested to meet all requirements in terms of operational efficiency and safety, we can ensure a simple, secure, and cost-effective installation process as well as a smooth and comfortable ride quality.

Our basement set traction machines are designed for locations that lack sufficient space above the hatch to install an overhead machine. The Standard Basement Set Machine features a narrow steel outboard stand which allows the traction wheel to project into the hatch, creating a perfect alternative elevator solution

The Overhead Deflector Machine is designed to simplify the elevator machine operation by eliminating the need for an additional sheave independently supported by the building structure.

| Title | Link |

|---|---|

| Adjusting Kits Brochure | |

| BULL 1150 LUBRICATION INSTRUCTIONS LEGACY H-W WORM GEAR MACHINES | |

| BULL 1152 GEARBOX CLEANOUT INSTRUCTIONS | |

| BULL 1187 – GT-Series Installation Manual Rev E | |

| BULL 1187-1 – GT-Series Service Manual Rev D | |

| BULL 1197 – GT-Series Shaft Retrofit Manual Rev B 04Dec23 | |

| BULL-1197S-GT-Series-Shaft-Supplemental-Rev-B-04Jun25 | |

| Geared Machine Maintenance and Troubleshooting Instructions (BULL-1140) | |

| Geared Machine Motor Alignment Procedure (BULL-1005) | |

| Geared Machine Motor Alignment Procedure with Cables on (BULL-1006) | |

| Geared Machine Replacement Parts Instructions (BULL-1141) | |

| GT11 – Geared Traction Machine | |

| HW_GT31 Flyer | |

| HW_GT31 Flyer | |

| Installation Procedure for Geared Thrust Bearings – Castle Nut (E-127) | |

| Installation Procedure for Geared Thrust Bearings (E-126) | |

| Instructions for Installing Geared Machine Housing Seal (E-121) | |

| Isolation Bracket Shim Instructions (E-175) | |

| Replacement Bearings and Seals for Geared Machines (E-130) | |

| Traction Wheel Driver Boss Drawing (E-155) |

Additional resources are available in the